SELECTION, INSPECTION, AND SAFE USE OF SHACKLES

Selection, Inspection, and Safe Use of Shackles

Lifting operations do have the potential to cause incidents, from uncontrolled movement of loads and dropped objects impacting people, assets, and the environment in proximity of the operation. The management of all rigging and lifting operations by appropriately trained, qualified and experienced personnel is a statutory/legislative requirement. Safety of personnel is considered the primary consideration followed by the safe transfer of materials and loads with minimal risk of damage. Rigging and Lifting equipment is made up of a variety of complex components, each playing an important role in the arrangement. Shackles are usually among the most integral components and although they are not the largest component in the rigging, they play an important role

Lifting Equipment Definition

Fundamental principle – all lifting equipment should be of adequate strength, sound material, of good construction and suitable for the lifting operation it must perform.

Shackle is a component consisting of 2 easily separable parts: the body and the pin. They play a very important role in rigging and lifting and are commonly split into two major categories:

- Anchor Bow Shackle

- Chain Dee Shackle

Both shackle categories are available in Safety Pin and Screw Pin.

Lifting Equipment Inspection Services

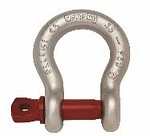

Screw Pin Bow Shackle

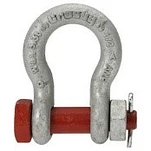

Safety Pin Bow Shackle

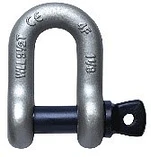

Screw Pin Dee Shackle

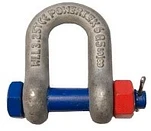

Safety Pin Dee Shackle

Shackle – How to Select?

It is important to select the right shackle type, size and working load limit (WLL) for the application and rigging arrangement to ensure the load being lifted is balanced properly and securely on the shackle and that the overall effective utilisation of the assembly is guaranteed. Selection should also consider any increased loadings due to sli0000000ng angles – as the angle increases, so does the load in the sling leg and any shackle attached. It is important to consider the difference between Safe Working Load (SWL) and Working Load Limit (WLL) when considering shackle selection. Dimensions of the shackle will be controlled by the hole diameter and the thickness of the material of the lifting eye (padeye).

Safe Working Load (SWL) – refers to the maximum weight (mass) certified by a Competent Person (Qualified Lifting/Integrity Engineer/Inspector) which a shackle may raise, lower, or suspend specific to the operational conditions of its use.

Working Load Limit (WLL) – refers to the maximum weight (mass) which a shackle is designed to raise, lower, or suspend.

i. For Bow type shackle and Dee type shackle, selection will depend on the number of components/attachments being connected to the shackle. For a 2-point connection, the Dee shackle is preferred but for a 3 or more components required to be connected, the Bow type shackle is more suitable.

- Generally, safety pin bow shackle is preferred but for certain applications, screw pin bow shackle often offer more practical means of connection and disconnection, i.e. subsea diving operations.

Shackle – How to ensure Safe Use?

After selection but before it is put into service/operation, it is important to make sure the shackle is in good condition. Conditions to consider before use:

- The shackle’s pin works freely and fits correctly.

- The pins are undamaged, have no considerable wear and fit properly from the opposite side of the shackle.

- The load line and jaw opening are aligned.

- The pin is always seated and is ‘matched’ to the body.

- When you use shackles in conjunction with multi-leg slings, you must consider the angle between the legs of the sling

- The shackle is the right material, size, and type for the proposed lift.

- It is important that on shackles fitted with a nut and bolt pin, the length of the bolt’s plain portion will cause the nut to jam on the inner end of the thread, and not on the shackle’s eye. This would leave the bolt free to rotate.

- Shackles are stored in a dry, cool place.

The right kind of design makes all the difference in ensuring that the shackle works correctly.

Shackle – Pre-use, Inspection & Compliance?

Pre-use

Prior to use, the following checks should be made:

- The SWL / WLL is adequate for the load.

- The shackle has an identification mark (ID) or number and correct colour code (if applicable)

- Remove pin and check for wear, deformation and cracking on the thread or pin body.

- Check body for wear, deformation, and cracking.

- In the case of safety pin shackles, ensure split pins are fitted securely.

Compliance

Lifting Operation Lifting Equipment Regulation LOLER 1998 (Regulation 9) requires lifting equipment to be thoroughly examined before being taken into use for the first time, at intervals throughout its life and after exceptional circumstances.

As a Lifting Accessory, shackles shall ne thoroughly examined at least every 6 months to ensure that health and safety conditions are maintained, and that any deterioration can be detected and remedied in good time.

Inspection

Inspection is not only a compliance requirement but a necessary requirement to prevent equipment failure. Inspecting rigging equipment frequently ensure continues safe use of equipment. Inspection should ideally happen, before use (pre-use), during operation and after use and at specific intervals (compliance). Regular inspection as discussed, checks for deterioration but if any of the following conditions are noticed, the shackle should be removed from service and replaced:

- Distorted shackle jaws or pins.

- No safe-working load (SWL) stamped on the shackle body.

- The shackle pin does not work freely or fit correctly in the shackle’s opening.

- The pins threads are damaged, worn down or do not easily screw in from the opposite side of the shackle.

- The unthreaded hole is enlarged — a hole too big places unnecessary strain on the loaded shackle.

- The shackle has worn by more than 8% of its original diameter.

Still not sure about selection, safe use, and inspection of your rigging equipment?

The Answer:

At JC International, we are happy to offer our expertise in helping you establish a strategy to ensure you comply with standards and regulations. A LOLER Inspection Scheme can be developed and implemented by our LEEA Qualified and FGN Factory Act. Approved Inspection Engineers to national and international standards. You would have remote and real-time access to your comprehensive lifting equipment register and digital and hard copy reports. The whole process would be managed professionally and cost-efficiently.

Our focus is to provide a world-class service to ensure that our clients as duty holders, can use their lifting equipment, perform lifting operations safely whilst also demonstrating compliance with national and international regulations.

Leave a Reply