The Critical Role of Scaffolds in Construction and Maintenance Projects.

What is a Scaffold? A scaffold is a temporary structure used to support workers and materials during the construction, maintenance, and repair of buildings, bridges, and other ma

JC International: NDT Training and Courses in Nigeria.

Non-destructive testing (NDT) is becoming a highly sought-after skill, gaining momentum in various sectors, including construction, automotive, mining, agriculture, power generatio

Rigger Training: A beginner’s Guide.

Rigger training is essential for anyone looking to enter fields like construction, mining, agriculture, and oil and gas. This specialized training ensures that individuals are equi

5 DO’S and DON’TS OF A BANSKMAN.

Every field and profession has standards and rules governing the operations of its personnel. These personnel are expected to carry out certain duties and are also prohibited from

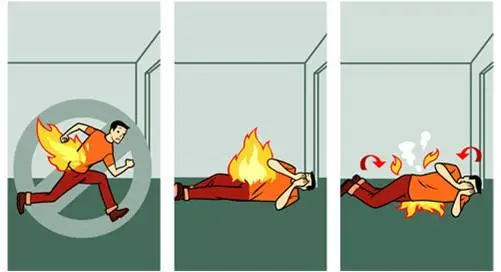

Safety Tip: What do you do if your clothing catches fire?

When faced with the terrifying situation of your hair or clothes being on fire, what will you do to prevent burns or even death? The safety phrase “Stop, Drop, and Roll

NDT Methods ANd Trainings You should know.

What is NDT? NDT stands for Non-destructive testing. It refers to the skill and technique used to inspect, evaluate and test materials to determine product quality and integrity wi

Lube oil flushing- All you should know

what is lube oil flushing? Lube oil flushing is a critical maintenance procedure used to clean and maintain lubrication systems in various types of machinery and equipment, particu

7 Benefits of health and safety Training for your organization.

‘Safety first’. It is not enough to just echo or write it down; we must practice it as individuals and organizations. The health and safety of employees in the workplace is cru

The Role and Duties of a Rigger.

Although a rigger has numerous duties, we will focus on 5 duties of a rigger. To understand the duties of a rigger, it is essential to define rigging and who a rigger is. What is R

Proactive Stuck Pipe Preventive Measures You should know.

A stuck pipe poses a significant challenge to drilling operations, leading to costly downtime, equipment damage, and safety hazards. The hindrance it causes can be frustrating for